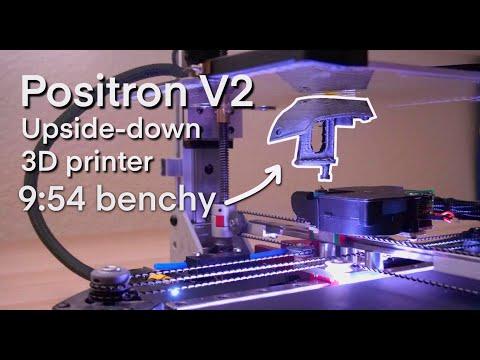

It’s rare these days for a new FDM printer to come along that sparks our interest, but the [Kralyn]’s Positron managed to do it. (Video, embedded below.) It prints upside down and packs down into a filament box while still boasting a print volume of 175 mm x 176 mm x 125 mm.

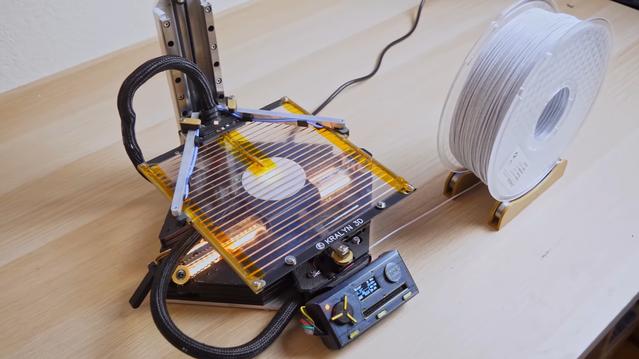

Unlike most 3D printers, the hotend and XY-gantry is mounted below the build plate, directly onto the base. You might assume that a printer needs to extrude plastic with gravity to work properly, but the real action is in the smooshing of the plastic layers. It appears that it might even improve bridging since the hotend is supporting the plastic as it gets extruded. A clear glass build plate is used, with the same heating strips found on the rear windows of most cars. This also allows the user still see the part, and provides the added advantage of being able to quickly spot bed leveling and adhesion problems.

Another interesting side effect of this arrangement is rigidity. There is no need to suspend the XY gantry with the heavy hotend in the air, so it can be mounted directly on the thick aluminum base plate. It uses an H-bot style gantry, with Synchromesh timing cables instead of belts, which eliminates the concern of belt twist. To get the best possible print volume within the size of a filament box, the gantry axes are arranged diagonally across the base plate. The Z-axis can disconnect and lay flat on top of the printer and uses the linear rails to keep it perfectly straight and perpendicular when mounted.

To reduce the hotend’s height to fit the available space, the filament comes in from the side and the molten plastic makes a 90-degree turn before being extruded. It took [Kralyn] a few revisions to get this to works right, but the large volume of the melt zone allows for increased flow. However, we suspect it might also make hotend maintenance slightly more difficult. The only other concerns we have are the reduced visibility of the printed part and the possibility that bits of plastic might drop into the gantry mechanism and jam it. As far as compact folding printers go, this is probably the best design we’ve seen so far. The design is licensed under CC BY-NC, and all the design files are linked in the video description.

Thanks for the tips [IraqiGeek] and [Jasper Jans]!