LightForce Orthodontics, a provider of custom 3D printed orthodontic brackets, has raised $50 million in its latest round of Series C funding.

The funding round was led by investment firm Kleiner Perkins, and saw participation from LightForce Orthodontics’ existing investors Matrix Partners, Tyche Partners, and AM Ventures. The investment follows a particularly successful year for the company, in which it posted a 500 percent revenue growth rate, developed two new products, and tripled its team.

With the new funds, LightForce Orthodontics will look to offer training to orthodontists in order to maximize the technology for their patients, alongside continuing to scale up its operations and go-to-market efforts.

“LightForce was founded to provide fully customized, USA-made treatment options for orthodontists interested in offering modern braces to their patients,” said Dr. Alfred Griffin, LightForce CEO and Co-founder. “The investment from Kleiner Perkins allows us to continue creating mass-customized braces that enable orthodontists to provide a personalized patient experience within an industry that has not evolved the use of braces in the last 25 years.”

One size fits one

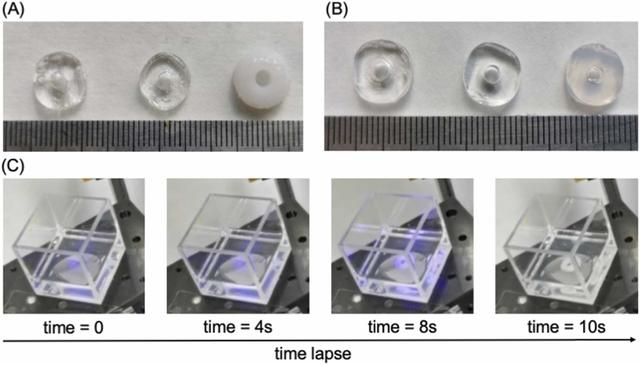

LightForce’s 3D printing technology is used by orthodontists to produce custom individualized braces for patients, with the intention of reducing the number of follow-on visits for bracket adjustments.

The company launched its first fully customized 3D printed braces in July 2019, fabricated using a light-based additive manufacturing system and cloud-based CAD software. After receiving FDA clearance, its braces entered the market later that year.

In September 2020, the firm raised $14 million in a Series B funding round to further develop its technology and scale up its operations to meet the increasing demand for its braces. The company is seeking to move away from the age-old ‘one size fits all’ philosophy that dominates orthodontics, and instead enable mass customization and personalization through patient-specific bracket systems.

Operating under the slogan ‘one size fits one’, the LightForce service enables orthodontists to send in a 3D scan of a patient’s teeth, along with their treatment plan, from which LightForce will print the corresponding brackets and trays in-house before sending them to the practice.

The brackets are 3D printed in a dental ceramic with mechanical properties comparable to those of traditional injection-molded brackets, however fit the unique tooth morphology of each patient. The technology reportedly delivers shorter lead times, fewer appointments, and a more efficient experience for patients, and is able to deliver precision down to a thousandth of a millimeter.

“Without LightForce, patients today would likely be wearing the same sort of braces their parents did back when they were teenagers,” Griffin said. “With these new funds, LightForce will further champion the unmet needs of the modern teen market by complementing aligner cases and allowing orthodontists to take their practices fully digital, while capitalizing on the advancement of 3D printing technology, modern materials, and advanced application-specific CAD software.”

Scaling up personalized braces

Both the LightForce brackets and the trays they come in are 3D printed, enabling orthodontists to place the brackets in the exact desired position on a patient’s tooth. Over the last year, LightForce has developed new products such as its Light Bracket, its line of translucent braces. A more aesthetic option for patients, the brackets appear to be the same color as the teeth, leaving them much less visible.

“A patient’s teeth are all unique as snowflakes, and now orthodontists have the technology to account for that individualism in their treatment plan, just as they have with their aligner cases,” Griffin continued. “We are excited to continue implementing 3D printing technology in orthodontics in new and innovative ways to create a new standard of care for all braces patients.”

Scaling an operation where each set of ceramic brace brackets is custom printed for each patient will certainly throw up complex challenges, however the latest $50 million cash injection will go some way towards achieving this, Griffin hopes.

“Scaling, mass customization is a very unique problem that most talk about in theory, but very few have dealt with in practicality,” he said. “There’s around 200 of us in the company right now, and we will probably double that over the next year. Sales and engineering are probably going to be the biggest expenses, but in terms of headcount, we will need to grow the most in manufacturing technicians, both in terms of physical and digital manufacturing.”

Taking the lead in the Series C funding round is Kleiner Perkins, which cut its teeth in the orthodontics business some 25 years ago after investing in dental aligner manufacturer Invisalign.

“LightForce’s innovative approach to an industry that has lacked technological disruptiveness for the past 25 years is what initially attracted us to this investment opportunity,” said Wen Hsieh, Partner at Kleiner Perkins. “Having previously invested in the first digital revolution of orthodontics decades ago through Align Technology, Kleiner Perkins is excited to invest in the second wave of orthodontics digitization through LightForce.

“We’re excited to partner with Co-founder-CEO Alfred Griffin and the Lightforce team to leverage the latest 3D printing technology to further enhance the doctor and patient experience with bracket-based orthodontics.”

3D printing in the dental sector

Orthodontics is one of the largest commercial applications of 3D printing technology, with the dental sector benefiting greatly from advancements in additive manufacturing.

One such advancement is the recent slew of announcements from 3D printer manufacturer Formlabs concerning its dental 3D printing business. The firm’s Fuse 1 SLS system has been validated for the 3D printing of orthodontic models, its popular Model Resin is to be reformulated to double its printing speed, and the Form 3B, Form 3BL, and Fuse 1 printers have all been validated for integration with software developer 3Shape’s Clear Aligner Enterprise platform.

Elsewhere, industrial 3D printer manufacturer Desktop Metal’s healthcare subsidiary Desktop Health recently expanded its dental technology portfolio to deliver binder jet 3D printing capabilities to dental labs, while Dutch 3D printing material manufacturer Liqcreate has launched two new dental-oriented photopolymer resins.

Subscribe to the 3D Printing Industry newsletter for the latest news in additive manufacturing. You can also stay connected by following us on Twitter and liking us on Facebook.

Looking for a career in additive manufacturing? Visit 3D Printing Jobs for a selection of roles in the industry.

Subscribe to our YouTube channel for the latest 3D printing video shorts, reviews and webinar replays.

Featured image shows LightForce Orthodontics has raised $50 million in Series C funding. Photo via LightForce Orthodontics.