Digital transformation provides the manufacturing and design industries the opportunity to leverage digital technologies to improve speed and efficiency, increase production, decrease costs, and provide a better customer experience. This transformation is much more than just digitising paper-based processes.

It means the integration of technology into all areas of business and re-defining business strategies and creating new business models by harnessing technology. Customer demands have risen, and competition is fiercer than ever. In the post-pandemic environment, digitalization of production and supply chain activities is critical.

In a recently concluded roundtable organised by BW Businessworld with some of India’s top leaders associated with the manufacturing & design industry, a wide range of topics were discussed, including the need for digital transformation in manufacturing & design, the role of digital in syncing manufacturing & design, the need to embrace digital transformation, and how technology companies can help customers on their digital transformation journey.

Digital transformation has several advantages:

Samip Mutha, Vice President and Group Head – Digital at RPG Group, highlighted the advantages of automation in the manufacturing industry.

Mutha said, "Digital Technologies are helping in making the manufacturing industry safer and smarter as manpower is no longer required to work in an environment that is hazardous, mundane, and involves high fatigue. For instance, computer vision is now being used to conduct some of our most unsafe operations to sense human hands or photosensitive gloves that halt the machine automatically."

"Digital in manufacturing helps in delivering new business models and the new lines of revenue can emerge from moving to Smart Products. Products like Smart Tyre, Transformer or Meter can potentially generate new service revenue or develop a new business model involving a larger ecosystem at play. It also helps extend the product life as they are constantly being monitored for performance, reducing the cost of operations for the customers as well, "he added.

Mutha underlined that digital transformation is helping in making the environment cleaner too. He commented, "Digital also has a huge impact on ESG like IoT can be used for energy saving, minimal/no utilisation of water consumption in a plant or environmentally critical processes."

The majority of manufacturers have now joined the digital race:

Rohit Gupta, Head -Technology Center at Thyssenkrupp AG, said, "Distributed manufacturing can be referred to all the stakeholders in the value chain coming together, and leveraging connected networks to work in cohesion even though they may not be geographically located in the same place."

Gupta added that the majority of manufacturers are now a part of the digital transformation that is happening across the country.

He commented, "The Majority of manufacturers have already embarked on their joined the digital transformation journey. They are automating plants, increasing sensors, are integrating their ERP & CRM systems. A large amount of data is coordinated via the cloud, including data between plants, designs, vendors, and suppliers. Coordination does deliver value but higher levels of efficiency can be unlocked by leveraging technologies like AI/ML."

Gupta underlined the importance of using Condition Based Monitoring (CBM) systems with an example. He mentioned, "During the wake of the pandemic, we witnessed huge disruptions to the supply chain of materials as countries were forced to close their borders, bringing to fore the urgencyand the demand was for better usability of the supply chain to keep the factories running."

"As a result, technologies like predictive analytics, demand forecasting, and visibility across the supply chain are very helpful in maintaining production schedules to help tell the customers when a part will be delivered to them," added Gupta.

Manufacturing and design must be in sync:

Salil Lothe, Senior Director - Digital Transformation at Harman International, underlined that design and manufacturing, though dissimilar, are intertwined.

Lothe said, "Design and Manufacturing have historically seen as two different processes, two siloed teams, but the fact is that it is the same product on which people and processes are working. Fundamentally, it is the same set of data, parts & products."

"Studies have indicated that more than 50 per cent of the cost of manufacturing is influenced by design decisions. For instance, it includes decisions such as which materials to use, early sourcing decisions, and manufacturing feasibility. Hence, it is very important that these two remain in sync, "he added.

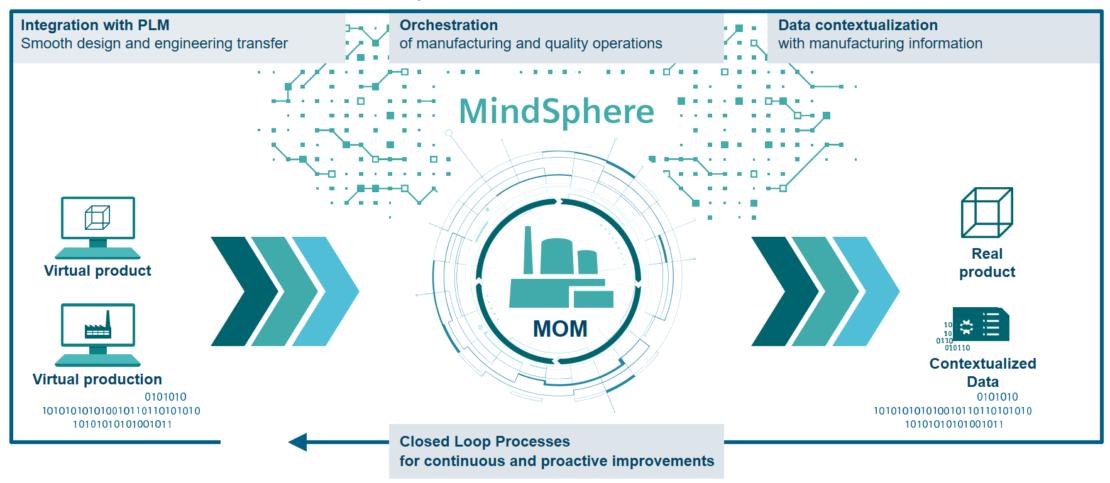

Lothe suggested that digital transformation is playing a major role in connecting everyone and taking decisions. He said, "Digital transformation is all about connected data, connected processes, and connected people – it is the digital thread. This helps in boosting cross-function collaboration, making decisions faster and better and improving reliability and visibility across the supply chain."

Ravi Kumar, Chief Digital Officer at Exide Industries, suggested that both the manufacturing and design industries have evolved with time.

Kumar said, "Historically, the manufacturing industry has been using software like MES, which helps with procedural enforcement. With the advent of the cloud alongside real-time IoT connectivity, the entire system has become even more flexible, contextual and can take decisions in real-time.”

"Similarly, on the design side, various systems have evolved, including CAD/CAM and PLM. This has helped in providing more immersive designs, 3D designs, and even 3D printing of the designs. Through AR/VR, one can even experience it, "he added.

Kumar explained that as technologies keep evolving in both segments, it results in providing new capabilities.

He mentioned, "Additional capabilities like adaptive manufacturing and highly customised products are now possible. For example, one can now alternately assemble a Maruti Suzuki Swift, Alto, and Brezza on the same assembly line. Also, the products are now getting personalised as per the consumer’s requirements."

The DNA of a successful digital strategy:

K V Veerapandian, Technical Sales Leader - Design & Manufacturing, India & SAARC at Autodesk underlined that though digitalization is important, the approach should always begin with defining a digital strategy.

Veerapandian said, "At Autodesk, we have worked with several companies, and we have noticed that those companies that are successful have three things in common - a general attitude of exploring what is thought to be impossible, including everyone in a conversation, and focusing on short term agility."

Veerapandian further elaborated on the components of a successful digital strategy.

He explained, "A successful digital strategy’s DNA lies in spending time figuring out how to convert the impossible into the possible with a top-down approach where the leadership makes company-wide decisions based on answers received from questions such as – where do we stand today, where do we want to be and what is stopping us from reaching our goals."

Veerapandian provided a recipe for success for manufacturing companies who want to get started with digital transformation.

He mentioned, "There are three steps to achieve success in manufacturing using digital transformation. Step one is to begin at the end, i.e. define your end state – this goal usually refines an existing business process."

"Secondly, once this goal is finalized, it should be communicated across the organisation. If you don’t get buy-in from the people you work with in your organisation, you will get compliance but not the commitment. The third step should be to get prescriptive on what needs to be done with people, process, and technology,” added Veerapandian.

Anjum Arora, Asia Pacific IT Director & Site Lead at The Boston Consulting Group, said that every organisation is now evolving and adopting technology.

Arora commented, "If you talk about organisations like L'Oréal, they do not call themselves beauty organisations but BeauTech, a combination of beauty and technology. We are witnessing a revolution of sorts where no organisation wants to be labelled as traditional or conservative, but bold and cutting edge and at the forefront of innovation."

"There is a paradigm shift as every organisation is becoming a tech organisation or a product organisation – more importantly, executive sponsorship right from the top (CEO, Board etc.) is very important for starting any digital initiative," she added.

Arora emphasised the importance of people in the successful implementation of any digital initiative. She said, "All digital transformations revolve around people at their centre, including those who want to implement them, drive their adoption, and leverage new ways of working. Hence, people need to be at the heart of the conversation and own the transformation journey. "

Digital transformation will revamp supply chain management:

Nitin Sambhare, Managing Director at Desmet Ballestra Group pointed out that the supply chain segment has generally been a laggard in the adoption of digital technology, but with rapidly developing technology, things can change.

Sambhare said, "We are working with data being made available from partners spread across the supply chain. In India or elsewhere, there is concentrated data availability and it is under tight control. This data is not easily available on the internet. However, with the advent of AI/ML, manufacturers can look into some of these critical challenges in a far better way by mining relevant data very effectively."

"The smooth functioning of the supply chain is very much dependent on the transparency and efficient usage of data. The challenge is how we use the data, and at the same time quickly adapt with the changing conditions," he added.

Sambhare underlined four distinct areas where disturbance is taking place – Planning, procurement, manufacturing and logistics."

He commented, "Planning is the most data-driven segment – because you want aggregation of demand across the whole supply chain. Digital technology can reduce the uncertainty that we face in our day-to-day lives. Not only can digitalization help with logistics, inventory or warehouse management, but it can also help in ensuring quality, and providing better demand forecasting using AI/ML algorithms."

Is a single template for digital transformation viable?

Sharad Kumar Agarwal, CDIO at JK Tyre, suggested that digital transformation as per a given template can only be done to a certain extent.

Agarwal said, "Digital Transformation can have a template to a certain level, but industry and organisation-specific customisations will also be required. Even if both the companies are making the same product, if there is a cultural difference, digital transformation will have to be tweaked accordingly."

Agarwal highlighted that as a result of digital transformation, all the functions are now on the same platform.

He said, "What this digital transformation has brought to the fore is that all functions, including procurement, design, manufacturing, marketing, and sales, are now connected, and anyone can feed into another and anyone can draw feed from another. This means that feedback from the customer is equally important for all the functions, including manufacturing, technology or design."

Agarwal provided an example to further illustrate his point. He explained, "No matter what industry you are in, if you know two months beforehand that the price of the raw material is going to increase, they can think of substituting it with a new recipe. All of these functions can work cohesively, feeding into each other to bring out the optimum best for the end consumer as well as the internal/external stakeholders."

Bringing together digital threads:

K V Veerapandian commented that they are working with an entire ecosystem of manufacturing partners to help them on their journey of digital transformation, and to help them reimagine their digital strategy.

Veerapandian said, "We help customers up-level their skills and help them deliver the innovation and productivity they are expecting to propel their business into the future."

"The heart of our mission for digital transformation is – convergence, collaboration, and automation. We bring design and manufacturing together on a single platform – connected data creates digital threads that tie it all together and drives this convergence, authoring a connected experience," he added.

Veerapandian underlined that creating a Common Data Environment provides one with a complete view of their products and processes. He mentioned, "It creates transparency at a global scale to offer actionable insights across your entire organisation so that everyone can make better decisions faster."

"Once you are connected and collaborating effectively, the next step forward is to automate- so we are also making automation accessible to everyone by building automation technology directly into our platforms, incorporating technologies like AI/ML," he added.

Veerapandian summarised by stating that the solution platforms and technologies that we are offering today are vendor agnostic.

He explained, "This helps connect all applications and data in the business seamlessly regardless of the vendor organisations. Flexible adaptable platforms give our customers effective control over the scope and the pace of their digital transformation journey."

The panellists concluded the roundtable by stating that digital should be used to build businesses and not just improve existing businesses and that the people are the biggest assets that determine an organisation’s success or failure.

Tags assigned to this article:Digital Transformation