In this edition of Sliced, the 3D Printing Industry news digest, we cover the latest business developments, partnerships, and acquisitions in the additive manufacturing sector.

3D Printing Industry will be heading to Frankfurt next week for Formnext 2021. You can watch our livestreams from the largest 3D printing event of the year on our YouTube channel. In this edition of Sliced you can see a preview of some of the news from the show.

Today’s edition features a host of new 3D printer launches, financial breakdowns, R&D funding updates, novel dental and automotive applications, military 3D scanning experiments, and an array of additively manufactured art installations.

Read on for the most recent updates from Farsoon, Nanoscribe, PostProcess, GE, BEAMIT, voxeljet, Xometry, Covestro, Shapeways, PrintParts, Authentise, Elementum 3D, Wematter, AddUp, Xpect INX, BCN3D, America Makes, the Spaghetti Detective and more.

System news from BOFA, B9Creations, Anisoprint and Raise3D

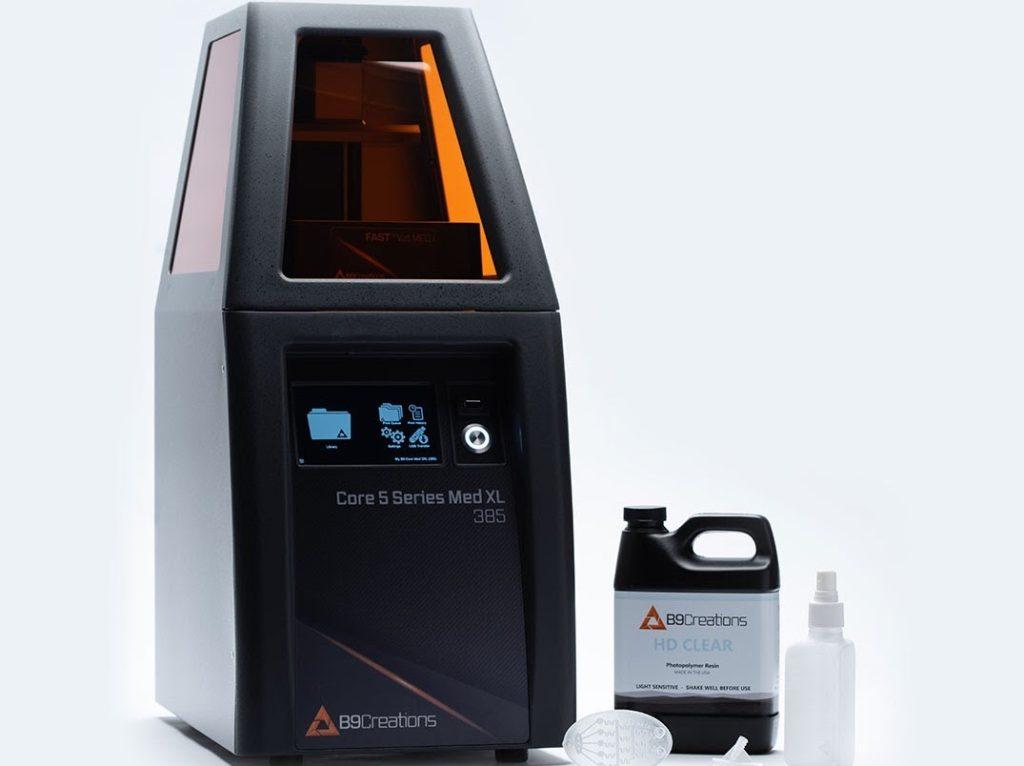

Starting this week with the latest in system hardware, Dakota-based 3D printer manufacturer B9Creations has released a new machine: the ‘B9 Core 5 Series XL – 385.’ Available in standard and medically-compliant ‘Med XL’ versions, the firm’s largest platform to date comes fitted with a 385-nm light engine, which enables users to print translucent and white materials with pinpoint accuracy.

Alongside its new machine, B9Creations has also unveiled its ‘HD Clear’ translucent resin, a material that’s said to be capable of yielding parts with a smooth, glossy finish, and after polishing or coating, be made to appear fully-transparent and ‘glass-like.’ The company will be demoing both these products and more at the MD&M Minneapolis event, where those interested can pre-order them if desired.

Elsewhere, continuous fiber 3D printer manufacturer Anisoprint has announced its intention to launch a “next-gen” composite machine at this year’s Formnext. According to Evgeny Babarykin, a designer at the firm, this upgraded PROM IS 500 system is set to be powered by BOSCH Rexroth’s CNC automation technology, which now works seamlessly with its existing software to boost user productivity.

“We’ve chosen MTX because it’s considered the most powerful CNC system solution on the market,” explains Babarykin. “In combination with these high-quality automation and mechanical components, open software systems allow no-limit possibilities for innovative technologies.”

Raise3D, meanwhile, has launched two new 3D printers with a suite of upgrades, which are designed to enable the small-batch production of end-use parts, tools and spares. Known as the ‘Pro3 Series,’ the dual-extruder machines feature interchangeable hot ends and auto bed levelling, as well as improved industrial repeatability compared to their predecessor, the award-winning ‘Pro2 Series.’

To access the full technical specifications and pricing information for Raise3D’s Pro3 and Pro3 Plus 3D printers, check out our full breakdown here.

Rounding off this week’s machine news with BOFA International, the fume and particle extraction technology developer has unveiled a new and improved ‘3D PrintPRO 4’ 3D printing ventilation system. The upgraded unit has multi-stage gas filtration and a deeper carbon bed than before, making it better suited to automated production processes like FFF, SLA, DLP, and material jet machines.

“The enhancements to our 3D PrintPRO range match the industry trend towards faster printing capability and larger build chambers,” explained Haydn Knight, Sales & Marketing Director at BOFA. “Our filtration system options for this market are improving all the time, underlining our leading position in meeting the needs of companies investing in the benefits of industrial additive manufacturing.”

Linköping, Queensland universities invest in 3D printing

Moving onto the education sector, Linköping University has signed a deal with SLS 3D printer manufacturer Wematter that will see its students equipped with the firm’s accessibility-oriented Gravity system and associated peripherals.

According to the university, it has invested in the equipment to enable its pupils to engage in advanced on-campus research, particularly within the fields of printable polymers and composites. For his part, Wematter CEO Robert Kniola, has also expressed pride that his company’s technologies are set to provide the next generation of engineers with the tools needed to thrive in their future workplace.

“Linköping University has an incredibly high quality in all its programs and graduates students with top grades every year,” said Kniola. “We hope that future engineers, designers, and other professionals will see Wematter as a natural part of their professional practice, thanks to the knowledge of additive manufacturing and the SLS 3D printer Gravity that is acquired during their studies.”

“I am proud that Wematter will be part of one of Sweden’s largest university engineering programs.”

Similarly, the University of Queensland has also expanded its 3D printing portfolio with the acquisition of AML3D’s wire arc manufacturing (WAM) Arcemy system. Bought for a fee of $400,000 (AUD), the 1.5 cubic meter-capacity machine and its broad alloy compatibility, are set to be deployed within ‘education and research and development’ applications.

“We are thrilled to be able to supply UQ with what we believe is the world’s most sophisticated integrated wire-based 3D printing unit,” said Andy Sales, MD of AML3D. “There is an expectation that we will work closely with UQ in the future around specific R&D programs that will benefit both parties in research, industry application and students’ base learning and research.”

Covestro, MakerBot and Nanoscribe to market new materials

Onto this week’s bumper material update now, and German polymer specialist Covestro has launched a new SLA resin, with the potential to simplify the 3D printing of investment casting patterns. Designed to address the sensitivity of certain alloys during casting, the material is said to result in parts with a ‘clean burnout’ and ‘low residual ash,’ helping users improve their process efficiency and part yield.

‘Somos WaterShed AF’ is also highly-stable thanks to its low moisture uptake, making it ideal for applications with tight tolerances, such as those in the aerospace or aviation industries. Interested parties can find out more and see the resin in-action at either the Investment Casting Institute Conference from 7-9 November 2021, or Formnext from 16-19 November 2021 in Hall 12.1, booth C11.

Elsewhere, the company has also extended its collaboration with Chinese 3D printer manufacturer Farsoon. Having installed Farsoon’s laser sintering systems at its Dutch and German facilities for the qualification of new TPU, PP and PBT materials, Covestro’s clients are now beginning to deploy the resulting resins within larger series applications.

Seifert Logistics Group, for instance, is said to be 3D printing TPU footwear parts using an SS403P machine at ‘high productivity levels,’ while partnering with an automotive firm has seen both Farsoon and Covestro help develop end-use interior car components, leveraging the legacy-DSM material Arnite T AM1210 (P).

Likewise, Stratasys subsidiary MakerBot has revealed a new fast-dissolving support material and ABS filament for use with its METHOD X machines. While the former dissolves in water, removing the need for solvents or time-consuming post-processing, the latter ‘ABS-R’ material is designed to tackle part cracking or warpage during printing, and yield more reliable plastic tooling and prototypes.

“Our goal with METHOD has always been to make industrial 3D printing easy, reliable, and accurate on a desktop 3D printer. With RapidRinse and ABS-R, we are continuing to deliver on that promise,” said Nadav Goshen, CEO, MakerBot. “Further, RapidRinse is another step we are taking with Stratasys in our ongoing efforts to support sustainable manufacturing practices and industry safety standards.”

On the bioprinting front, Xpect INX has unveiled a distribution partnership with microprinting specialist Nanoscribe, that will see the firms widen the accessibility of high-res biofabrication. Through the deal, the former’s HYDROBIO, HYDROTECH and DEGRAD INX N100, gelatin, hydrogel and polyester-based materials, are set to become available on Nanoscribe’s machines, broadening their applications.

“We believe that this agreement with the market leader in microfabriation will really open up the application potential of the biofabrication technology,” explains Jasper Van Hoorick, Project lead at Xpect INX. “By offering a whole range of next-generation high-resolution bio-inks, we believe that we can induce a paradigm shift in the field of microfabrication”.

Desktop Metal, BEAMIT and co. announce processing breakthroughs

Moving onto material processing and qualification news, Italian service bureau BEAMIT has developed a means of 3D printing the René 80 RAM1 nickel-based superalloy. Formulated using Elementum 3D’s ‘RAM technology,’ the firm’s metal is said to feature both a high melting point and excellent oxidation resistance, making it particularly well-suited to producing valve and turbine spares.

Industrial 3D printer manufacturer Desktop Metal has also announced the qualification of a new alloy for use with its Production System platform. Known as Grade 420 or ‘420 SS,’ the stainless steel is characterized by its high strength and corrosion resistance, which have seen it deployed to create everything from surgical and dental instruments to ball bearings, gear shafts, and high-end cutlery.

“Engineers continue to seek out metal additive manufacturing as a leading option to drive innovation in design and manufacturing,” said Jonah Myerberg, CTO and Co-founder of Desktop Metal. “We believe our qualification of 420 SS and other high-strength alloys will accelerate the deployment of our AM 2.0 solutions among customers looking to successfully mass-produce critical parts at scale.”

In more collaborative material qualification efforts, Fraunhofer IPA, the University of Bayreuth and 3D printer manufacturer voxeljet have joined forces to launch a ‘HSS Material Network.’ Designed to accelerate the R&D of 3D printable polymers, the service effectively sees voxeljet discuss material aims with clients, before referring them to a joint Bayreuth and Fraunhfoer team who work out parameters.

“The potential of AM has not yet been fully exploited as long as there are materials that cannot yet be printed,” said James Reeves, Global Director for Polymer Printing at voxeljet. “By collaborating and openly exchanging ideas with industry leaders and renowned research institutions such as Fraunhofer IPA, we are able to significantly accelerate the development of new materials.”

Finally, in this week’s material update, metal powder developer Blue Power has launched a compact new ultrasonic atomization system called the ‘AUS 500.’ Built to enable the small batch production of high-quality alloys, the machine can melt powders into any shape and be deployed to create custom materials, without the use of expensive filtering systems or the risk of alloy elements evaporating.

Business updates from Xometry, GE, Quickparts, AddUp and PostProcess

Kicking off this week’s business update with GE, the U.S-based power, aviation, healthcare (and 3D printing) firm has revealed that its revenue was flat during Q3 2021 at $18.4 billion. However, compared to Q3 2020, the company’s order backlog also grew 42% to $22.1 billion, thus it now says it expects to achieve “revenue growth, margin expansion and a higher free cash flow in 2022.”

Those interested in exploring GE’s full financial results for Q3 2021 can do so here.

3D Systems’ former on-demand manufacturing division, meanwhile, has officially begun trading independently under the revived Quickparts moniker. Having been sold to Trilantic for $82 million in September, the firm continues to offer prototyping and short-run production services via its team of 300 employees and fleet of SLA, SLS, FDM 3D printers, as well as its CNC machining and sheet metal systems.

Over at Xometry, the manufacturing marketplace has launched an upgraded version of its app for design platform Autodesk Fusion 360. Suitably-named ‘Version 2.0,’ the update offers users in-app manufacturability feedback, allows them to upload multiple parts at once, and to effectively prototype products at pace.

“We are thrilled to deepen our partnership with Autodesk with Version 2.0 of the Xometry Autodesk Fusion 360 app,” said Randy Altschluler, CEO of Xometry. “Now designers can get all the key information they need – pricing, lead time, and manufacturability feedback – through the app while they are designing their parts.”

The app is free and can be downloaded directly from the Autodesk Fusion 360 App Store.

Lastly, in terms of business news, French industrial 3D printer provider AddUp has announced a partnership with post-printing specialist PostProcess. Together, the firms are working to integrate their technologies at AddUp’s French and U.S. facilities with the aim of improving 3D printing’s scalability within the aerospace, energy and automotive sectors, and they’re already said to have made part quality progress.

“Digital integration in the post-processing of AM is the point we were looking for to improve the value chain,” said Medhi Offroy, Post-processing Methods Engineer at AddUp. “[PostProcess’] DECI Duo solution is really interesting to reduce surface roughness on delicate metal 3D printed parts. Now we can reach inaccessible surfaces in a quick execution time.”

Additive applications featuring voxeljet, SLM Solutions and more

Leading this week’s latest 3D printing applications with voxeljet, the high speed sintering (HSS) system manufacturer has revealed that global automotive supplier Brose has become one of the first beta adopters of its VX1000 HSS system.

As part of the beta program, the companies are now working together to further develop the system’s automotive serial production capabilities. Following an initial joint three-month R&D phase at voxeljet’s headquarters in Munich, the system is set to be moved to Brose’s Additive Manufacturing Center in Coburg, integrated into its production set-up and optimized for use within customer-specific applications.

Voxeljet’s VX2000 3D printer has also found new applications in Finland recently, with the country’s Hetitec Oy foundry deploying the technology to create complex molds. Since installing the system earlier this year, the firm’s CEO Ville Moilanen says it has been able to expedite the speed at which it delivers castings, to the point that it’s now the “fastest freaking foundry in the whole of Scandinavia.”

Elsewhere in Germany, SLM Solutions has announced the sale of an SLM 280 3D printer to MacLean Additive, a division of leading automotive supplier MacLean Fogg Component Solutions. As the developer of Formetrix L-40, a tough, ductile steel powder, the firm now intends to use its new machine to produce hundreds of tools from the material, in a way that provides it with cost and performance benefits.

“We’re excited to partner with MacLean Additive on the industrialization and growth of their 3D metal printing product lines,” said Sam O’Leary, CEO of SLM Solutions. “Success with another innovative powder like Formetrix L-40 tool steel adds to the already impressive list of materials validated and proven on SLM machines.”

“We look forward to the mutual growth of Formetrix L-40 powder usage and the rapid adoption of SLM Solutions’ technology.”

Finally, in terms of application news, Moi Composites’ dental subsidiary Hi-Fiber has struck a deal with the Portuguese Malo Clinic that will see its continuous fiber 3D printed implants used as part of clinical trials. It’s thought that the agreement could mark the first in a series of similar collaborations between the firms, which serve to further the end-use application of additive manufactured dental reinforcements.

“It is the meeting of two excellences,” explains Michele Tonizzo, CTO and Co-founder of Moi Composites. “Malo Clinic represents excellence in dentistry. Our technological solution is the missing part of their protocol, we are the missing link to create the perfect smile. Collaborating with Malo Clinic was something we were aiming for from the beginning of Hi-Fiber’s development. It’s inspiring.”

Shapeways, Authentise, 3D Control Systems make software advances

3D printing service provider Shapeways has debuted its new ‘Otto’ Software-as-a-Service (SaaS) online platform. Having conducted a survey that found 88% of all 3D printing users face software-related issues earlier this year, the firm has released its updated web tool to combat this, by providing users with fully-digitized end-to-end workflows, which allow them to sidestep any unnecessary risk or costs.

“Our goal with Otto is to make it incredibly easy and fast for any manufacturer anywhere to benefit from 3D printing,” said Greg Kress, CEO of Shapeways. “Enabling seamless access to world-class digital manufacturing removes the required capex and hassles of setting up dedicated production capabilities. Manufacturers can sign up for Otto free of charge and start using our services right away.”

In software partnership news, U.S. 3D printing service provider PrintParts has also begun working with 3D Control Systems. Together, the firms aim to make every printed part both traceable and scannable, by combining PrintParts’ SmartParts authentication offering with 3D Control Systems’ workflow software.

“We saw the need for traceability within additive as it continues to prove beneficial for production purposes, and additive MES companies such as 3D Control Systems are already providing end-users with the visibility and control they need to scale into production applications,” stated Robert Haleluk, Founder & CEO of PrintParts.

AI-powered 3D printing application, The Spaghetti Detective, has now been used to watch back over 50 million hours of part production footage. In essence, the software monitors users’ prints in real-time via their webcams and intervenes when jobs look likely to fail, preventing damage to makers’ machines, while saving them from wasting any material.

To celebrate the number of prints it has saved by reaching its 50 million-hour milestone, the company is now giving away several prizes including a 3D printer. More details on the giveaway, which expires on December 1 2021 are available here.

Workflow software developer Authentise, meanwhile, has been granted an award of its own to the tune of £1.7 million. Issued by the Industrial Strategy Challenge Fund (ISCF), the funding will be used to develop and validate scalable digital tools, that improve the energy consumption and material efficiency of ceramic and metal additive manufacturing.

Set to be developed alongside Photocentric and research organization TWI, the data-driven tools are being designed so that users can identify and enforce industry standards during production, repeatedly and consistently. Once ready, the software will be tested via sample data provided by metal powder developer ICD, with results being validated independently by the Materials Processing Institute.

U.S. DLA identifies fresh 3D modelling benefits

The Defense Logistics Agency (DLA) has discovered that adopting 3D scanning within certain defense applications could also help it meet many of its 3D printing goals. While testing advanced imaging technologies, the organization found that they can be used by U.S. defense personnel to share models seamlessly across the Department of Defense’s Joint Additive Manufacturing Model Exchange.

It’s thought that 3D scanning ultimately has the potential to help military users match manufactured parts to a catalog model and figure out their national stock number, as well as improving how the DLA operates its Troop Support Product Test Center, and its process of contracting personnel, vendors and customers.

“Being able to send a 3D model embedded in a PDF that users can spin around… you can actually see it, and it’s more meaningful to you rather than just a bunch of words on a page,” explains the DLA’s Craig Gravitz. “Another benefit of 3D imaging includes the ability to gather information on a hard-to-manufacture part through reverse engineering,” added Jamie Hieber, a Lab Manager at the Center.

3D printing makes a splash at art exhibitions

Additive manufacturing’s artistic credentials have also been boosted recently, with the technology being deployed in the creation of several new exhibits. At Penn State University, a team from its Stuckeman School and College of Engineering have collaboratively built a new piece that’s inspired by their previous work, which finished second in NASA’s 3D Printed Mars Habitat Challenge.

Titled “From Earth to Mars and Back,” the piece features an array of images from the project’s research experiments, including different parts of the design and 3D printing processes, as well as full-scale prototypes of structures that could be additive manufactured either on Mars or here on terra firma. The exhibit is currently available to view for free at the university through to January 19 2021.

In a similar (albeit more abstract) artistic application, UNICEF has partnered with creative design agency Domestic Data Streamers to 3D print ten busts of real children on the streets of Paris. Built to highlight the issue of childrens’ mental health, the thought-provoking installation was built using BCN3D’s Epsilon W50 systems from ABS filament, and displayed in the French capital for three days.

3D printing material developer CRP Technology has also announced its segway into the world of art, via its participation in Italy’s ‘Ultraromanticismo’ exhibition. The firm’s Windform LX 3.0 Glass fiber-filled composite was used to create two generative masks, which went on display until last week, as part of design studio ‘MHOX’s’ “Collagene” exhibit.

“We are glad to take part along with MHOX,” commented Franco Cevolini, CEO of CRP Technology. “The ‘Collagene’ masks represent something innovative: a new concept of everyday objects – personalization – combined with a highly technological manufacturing technology, with high quality and a high-performance material.”

SEMI heaps praise on ‘Build Back Better’ bill

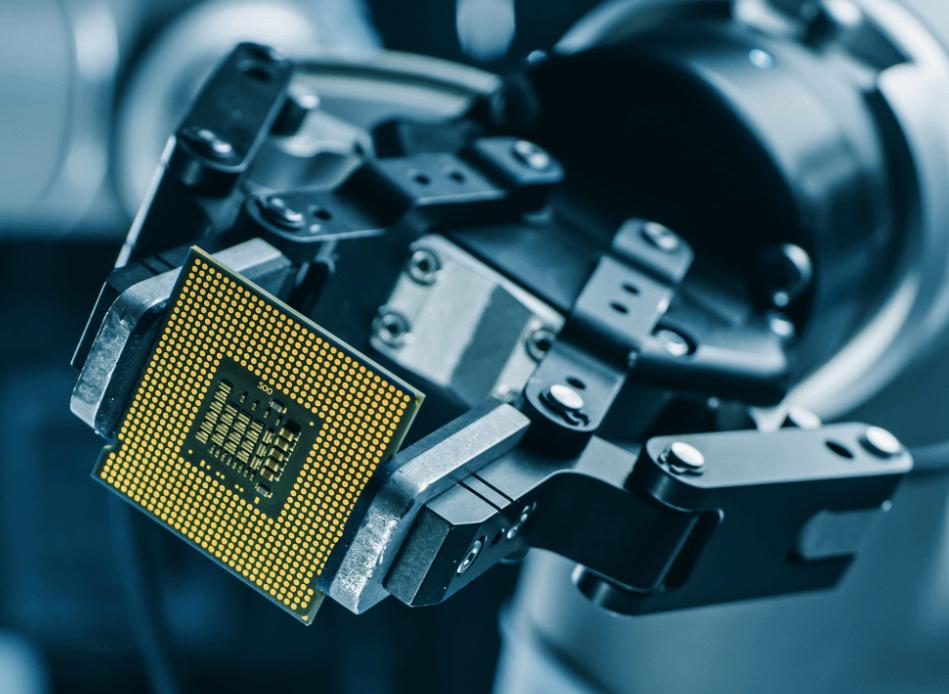

Electronics and manufacturing industry association SEMI has signalled its approval for the inclusion of an ‘Advanced Manufacturing Investment Credit’ in President Biden’s ‘Build Back Better’ reconciliation bill. As part of proposed changes, the bill will see the introduction of a 5% credit, potentially increasing to 25%, for any manufacturer of the infrastructure needed to create semiconductors before January 1 2027.

“SEMI is thrilled that a semiconductor manufacturing tax credit for the production of chips and semiconductor tools has been included in the Build Back Better reconciliation bill,” said Ajit Manocha, CEO of SEMI. “This credit will provide a strong incentive for the production of semiconductors and semiconductor manufacturing equipment in the United States and make the U.S. more competitive in this vital industry.”

Prototal and Nano Dimension continue expansions

Polymer and electronics 3D printing specialists Prototal and Nano Dimension have announced the continued expansions of their respective businesses. Having acquired Italian service bureau Prosilas, Prototal is now reported to have one of the largest 3D printing capacities in Europe, while users of its subsidiary’s services are expected to benefit from access to new molding and casting services.

Nano Dimension, on the other hand, has acquired PCB production equipment specialist Essemtec AG for a fee of $15.1 million, but this could rise to $24.8 million depending on its future performance. Considered to be a “leader in surface mount technology” by its buyer, the firm’s sophisticated dispenser is effectively capable of micro-dispensing materials onto circuit boards at high speed and efficiency.

Following the deal’s completion, Essemtec is expected to continue marketing its products to third parties, while helping integrate them into Nano Dimension’s 3D printing R&D. As of 31 December 2020, the firm had also brought in $17.2 million in revenue, and built up a backlog of $6.9 million by mid-September, income that Nano Dimension is now set to inherit.

Research innovation from ASTM, America Makes and more

Wrapping up this week’s update with the latest in research, Global standards developer ASTM International has announced a new Call for Projects (CFP). Specifically, the organization is inviting those unaffiliated with its AM Center of Excellence to participate in a ‘Research to Standardization’ initiative, which is designed to accelerate the development of 3D printing-specific standards.

The R&D topics set to be covered by the CFP include ‘DfAM,’ data sharing and acquisition, feedstock characterization, material processing and post-processing, as well as product testing, qualification and certification. Those interested in taking part can find out more via an upcoming webinar on the subject during December 8 2021, or access the brief via the ASTM site.

U.S. 3D printing accelerator America Makes, on the other hand, has just closed its Rapid Innovation Call (RIC), and unveiled the winners of its latest round of funding. The RIC’s $500,000 backing has been awarded to five projects investigating issues such as build interruptions, qualification best practice, defect detection and part lightweighting.

Set to take place across Ohio State University, ASTM, Open Additive and Pennsylvania State University, the projects are expected to be completed in May 2022 with resulting data being made available to America Makes members soon afterwards.

Lastly, in Saudia Arabia, researchers at the King Abdullah University of Science and Technology or ‘KAUST,’ have developed a novel means of aiding coral reef regrowth called ‘3D CoraPrint.’ The team’s project has essentially seen them adopt both molding and 3D printing to create calcium support structures, on which they’ve embedded coral fragments that actively encourage polyp colonization.

“Coral microfragments grow more quickly on our printed or molded calcium carbonate surfaces,” said Hamed Albalawi, one of the lead authors of the study. “We create [structures] for them to grow on so they don’t need to build a limestone structure underneath.”

More information about the scientists’ project can be found in their paper titled: ‘Sustainable and Eco-Friendly Coral Restoration through 3D Printing and Fabrication.’

To stay up to date with the latest 3D printing news, don’t forget to subscribe to the 3D Printing Industry newsletter or follow us on Twitter or liking our page on Facebook.

For a deeper-dive into additive manufacturing, you can now subscribe to our Youtube channel, featuring discussion, de-briefs and shots of 3D printing in-action.

Are you looking for a job in the additive manufacturing industry? Visit 3D Printing Jobs for a selection of roles in the industry.

Featured image shows the Sliced logo on top of three of UNICEF’s BCN3D printed busts. Photo via BCN3D.